Manufacturing

Our solutions

July 22 – 27 >> Join us at IDEF in Istanbul Expo Center in Turkey, at Booth #8-C12.

From heavy industry to the audiovisual industry, as well as a wide range of industrial sectors with complex environments, Socitec provides practical and effective solutions to protect and preserve systems and equipment subjected to shocks and vibrations, both during use and transportation.

Our solutions

Our solutions

Securing industrial transport

We design shock and vibration damping solutions for industrial packaging, providing additional protection to equipment and machines during their road, sea and rail transport between the manufacturer and the end user.

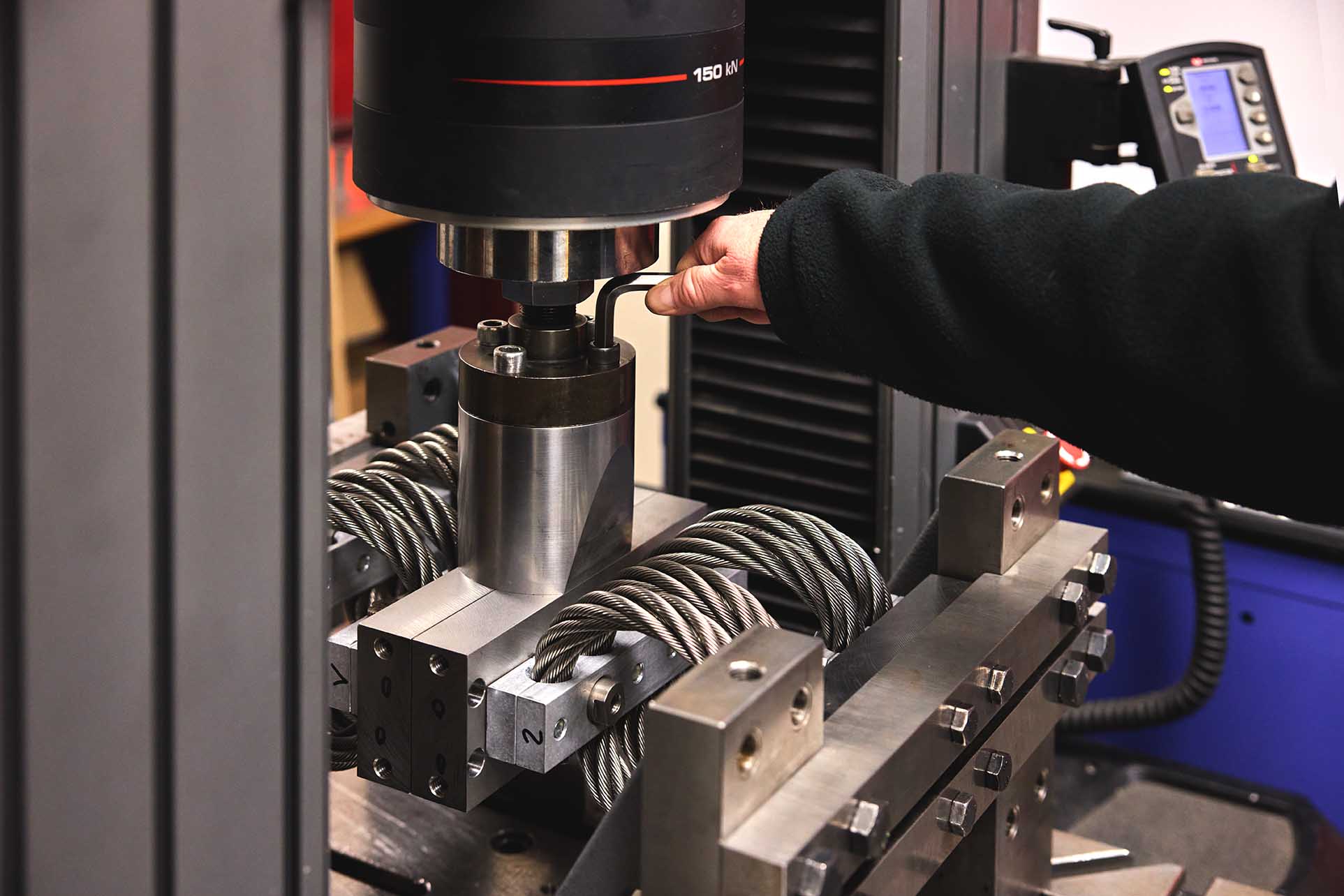

On-demand shock and vibration mitigation

We offer cable shock absorbers, elastomers, damped assemblies and spring isolators to protect industrial systems against repetitive shock and vibration, reducing the risk of damage and fatigue of exposed industrial equipment.

SOLUTIONS THAT MEET

INTERNATIONAL STANDARDS

Socitec’s product manufacturing complies with applicable standards in our clients’ countries.

To request additional information or share your specific needs, we invite you to contact our Socitec teams via our contact form or by phone.

DISCOVER

OUR SERVICES

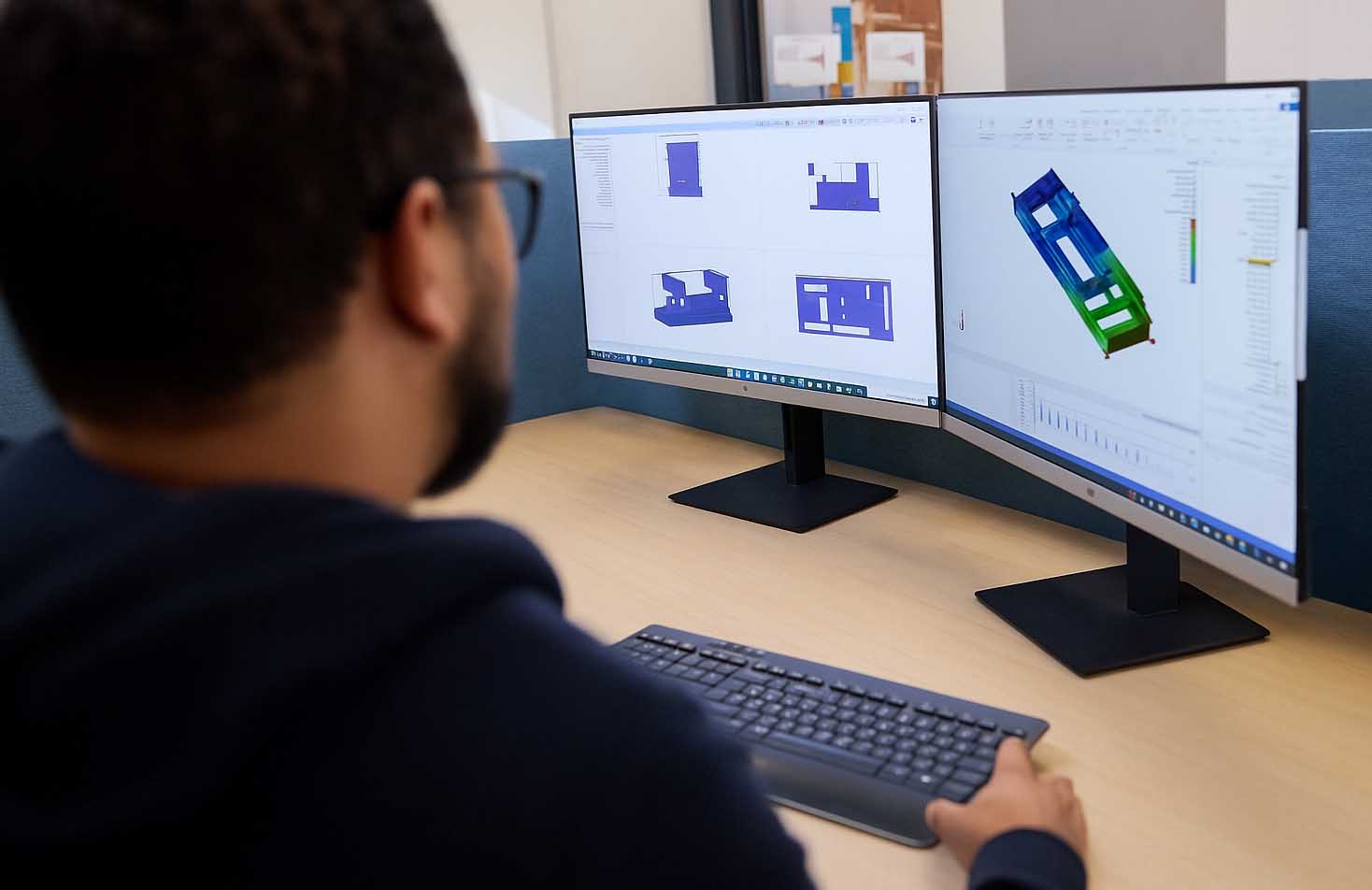

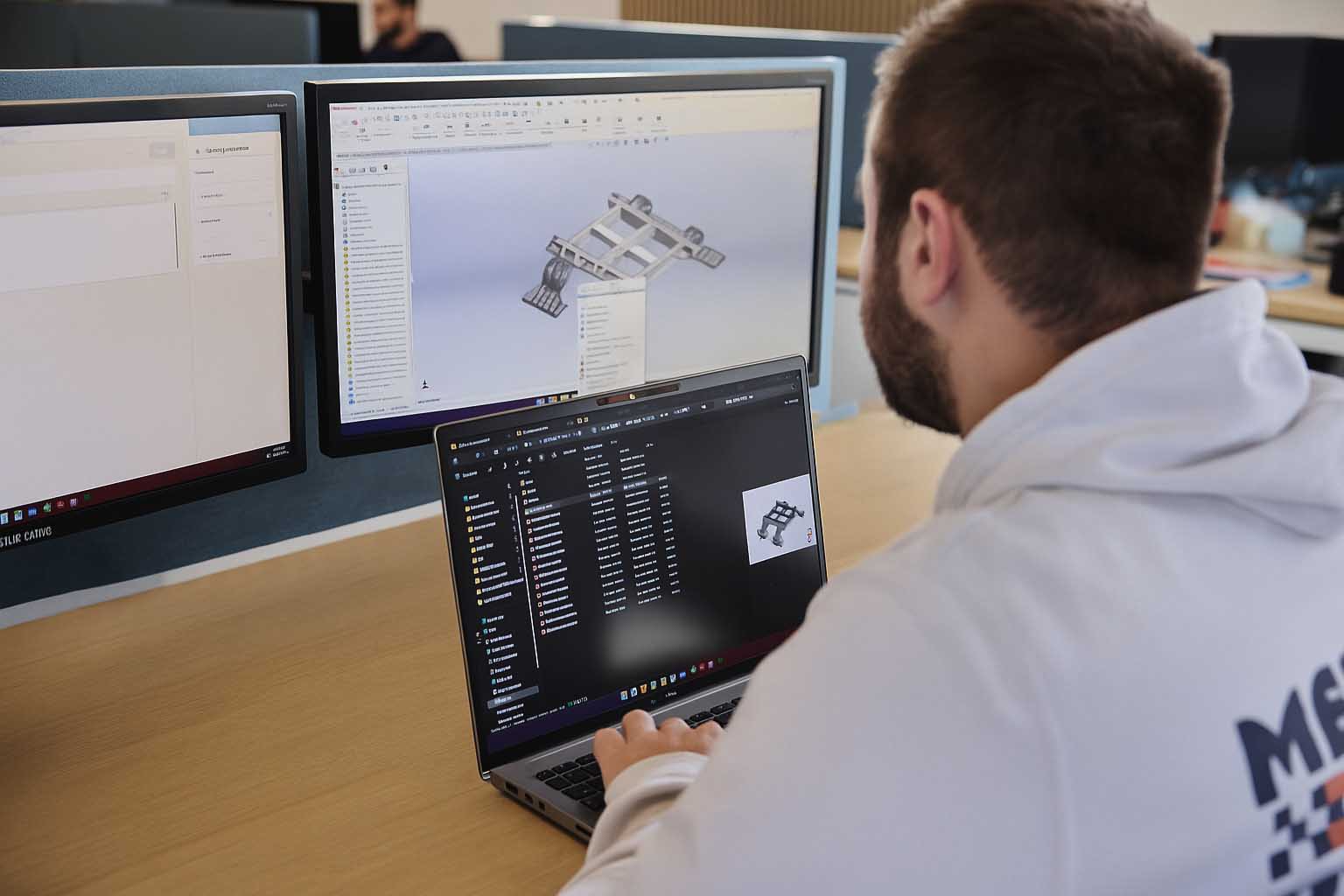

Our modeling and simulation tool for shock and vibration isolation for all types of applications

Sizing with finite element analysis

For the development of new products and the validation of the definitions of our technical solutions

Problem Diagnosis and Solution Validation On-Site

Master Anti-Vibration Systems

DISCOVER

OTHER APPLICATIONS